1. It's Not a Frame

Rimless is in its own category for good reason, says Larry Guess, ABOC: "A frame has an eyewire (whether metal or plastic) that 'frames' the lens completely. In the case of semi-rimless, the lens can rest against a top rim and be secured by a nylon string. Rimless is really a mounting where the lens has two or more drilled holes and is attached to end pieces/ temples and bridge by screws and nuts or a compression or tension type fastener."

2. Rx Considerations

In the past, higher prescriptions were a no-no for rimless mountings. Now, says Michael DiSanto, ABOM, most prescriptions can be accommodated, but you should consider which mountings complement the prescription. "When you get plus or minus lenses with powers above 8.00 D, it begins to offset the rimless advantage," he says. "Do not fall prey to the fallacy that a lighter frame will solve overall eyewear weight problems, as the lenses determine most of the weight. Choosing a rimless mounting will not make heavy lenses lighter."

In general, Mr. DiSanto cautions:

• High power minus is more complicated with rimless and semi-rimless mountings.

• High power plus edges can be too thin and often do best with semi-rimless mountings.

• High cylinder (thick edges and backside curvatures) may affect the mounting.

• For progressives, be sure to supply enough vertical depth for a proper fit.

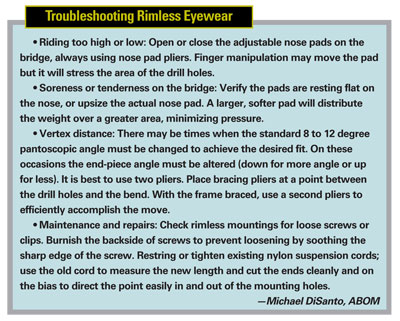

If you don't already have pliers such as these on hand, you should have them for proper adjustment of rimless mountings. These, along with other tools specifically designed for rimless mountings, are available from suppliers such as Western Optical Supply, Hilco, Sadler and Vigor/Grobet.

3. Lens Materials Matter

Choose polycarbonate or Trivex to eliminate the cracking, chipping and breaking that made glass a poor choice and plastic less than ideal, says Mr. DiSanto. Both offer a high index of refraction and are lightweight. Polycarbonate offers proven strength and impact resistance, and Trivex is well-suited for drilled mountings, as it lacks internal stress and will not crack or craze.

4. Strong, Flexible Mountings

Leading materials are surgical stainless steel, copper beryllium, magnesium and titanium. Mr. DiSanto notes that these are all stronger and more flexible than previous mounting materials. Some frame manufacturers have developed proprietary materials that are a fusion of the above.

5. Extra Fitting Care

Mr. Guess cautions you to take extra care when measuring seg height and optical center. "You have more freedom with lens size and shape, so it's not uncommon to realize that you forgot to take into account a deeper B measurement than what is represented on the sample mounting," he notes. Beware also of temple length, which may be difficult to modify in thin rimless temple materials.

6. Before You Dispense

Take extra care when handling or inspecting rimless mountings. Mr. Guess says that when placing the mounting on the lensmeter, be sure that the bottom lens edges are secure and flat against the lens table and that the temples are not in contact with any part of the lensmeter. Inspect to make sure the lenses are securely fastened to the mounting, drill holes are the same on both lenses and there are no "sparklers," micro-cracks or star cracks around the drill hole. Mr. Guess notes that it's critical to perform bench alignment: "Once the mounting is on the customer's face if the fit isn't close to optimal at first that product will never 'feel right' to the customer no matter how much alignment and adjusting is performed." It's a good idea to place a towel on the bench top and then place the mounting on that towel to prevent any possible scratching or chipping of the exposed lens bottom edges.

7. Dispensing

Mr. Guess suggest that you should examine the placement of the frame even more carefully than usual. If progressive lenses are being fitted, use verification masks. Refrain from bending the temple paddles/tips with your fingers without heating the temple covers first; the thin temple will bend much more easily and accurately when it is properly heated.